Preventing the evaporation of water by 90-95 percent and preventing the growth of algae, due to the presence of floating covers inside the tanks or covers on the tank, which in addition prevents the entry of dust from the wind and insects into the tank

They have great tensile strength

They have high resistance to change in length due to heat

They are resistant to strong winds

They have sufficient resistance to aeration in wastewater treatment projects and fish and shrimp farming

Using the minimum possible space to store water in different volumes, even inside indoor halls

The quantity and quality of water in these tanks can be easily measured and controlled on a daily basis

Prefabricated water tanks are completely bolted and easily assembled, disassembled and moved

They have a precise design in terms of shape and high mechanical strength, under the ISO standard

They are offered in different sizes and volumes from 100 to 1775 cubic meters and can be easily installed in the desired location with minimum number of people and in a short time

Capabilities of prefabricated water tanks

Application of prefabricated galvanized tanks

Galvanized prefabricated tanks, which are available in sizes of 50 to 2000 cubic meters, are fully bolted and can be dismantled

:Tank body

The body of prefabricated tanks is made of high strength galvanized steel (S280GD)

The lifespan of the tanks: 25 years

the height of the tanks is 0.75 meters to 4.57 meters

Inner covers (liners)

The liner of each tank is different according to its application

:Types of liners

1 mm liners suitable for storing drinking water with high resistance to sunlight and repairable with glue

0.75 and 0.5 liners with very high resistance to sunlight and chemicals and suitable for water storage Drinking and agriculture

liners 0.5 mm - PVC - with the possibility of storing food and easy repair

:Anti-algae coatings

Anti-algae covers are used to prevent the growth of algae in the water and to prevent dust from entering the tank

These covers are of two types, which are determined according to the diameter of the tank

:Tensioned AA-Cover

This cover is made of polypropylene and can be supplied in any size, but it is mainly used for tanks with a diameter of about 11 meters

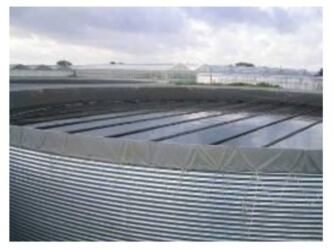

:Floating AA Cover

These covers are used for tanks with high diameters and are placed floating on the tank

The permeability of these coatings to water is 10ltr/m/sec

:Tank with metal roof

Recently, in order to ensure the health of stored water, metal roofs are used in prefabricated tanks

Metal roofs increase the cost of tanks. But such tanks with metal roofs are recommended for drinking water

Currently, the maximum diameter that can be used in metal roof tanks is 14.63 and the height is 4.57 meters

:These tanks can be found in

Greenhouses

factories

sports complexes

flower and plant breeding centers

parks

villages

next to construction projects, etc., and also according to the type of water consumption, both drinking and agricultural water

Comparison of concrete tanks compared to prefabricated water tanks

Concrete tanks are much more expensive than prefabricated water tanks

The installation of concrete tanks requires more time and they cannot be used immediately after construction because the concrete must harden, while prefabricated water tanks are not like that

Prefabricated water tanks can be dismantled and moved, but concrete tanks are not like this, so prefabricated water tankers are flexible

Concrete tanks need a heavier foundation compared to prefabricated water tanks

Due to the presence of hydrogen sulfide in urban and rural wastewater, which causes concrete to crumble, the use of concrete tanks in this regard is not appropriate at all

Concrete bursting, especially in winter, is very important in the concrete structure of storage tanks, sewage treatment plants, transmission lines and water distribution networks

Concrete tanks, unlike prefabricated water tanks, have time (seasonal) and location limitations in construction and installation

Although concrete is a popular and widely used material in construction materials, it also has some weaknesses. Such as low tensile strength, low formability, low energy absorption, shrinkage and shrinkage of concrete, followed by cracks caused by it and finally, cracks caused by improper processing and hardening of concrete (Cracking hardening and curing

Prefabricated galvanized water storage tanks

سبد خرید